Recent Work

Install of a new control systems

We optimize production equipment to build a better future for American manufacturing using Rockwell Automation. This project used Studio 5000 and FactoryTalk View Machine Edition!

Recent Work

Install of a new control systems

We optimize production equipment to build a better future for American manufacturing using Rockwell Automation. This project used Studio 5000 and FactoryTalk View Machine Edition!

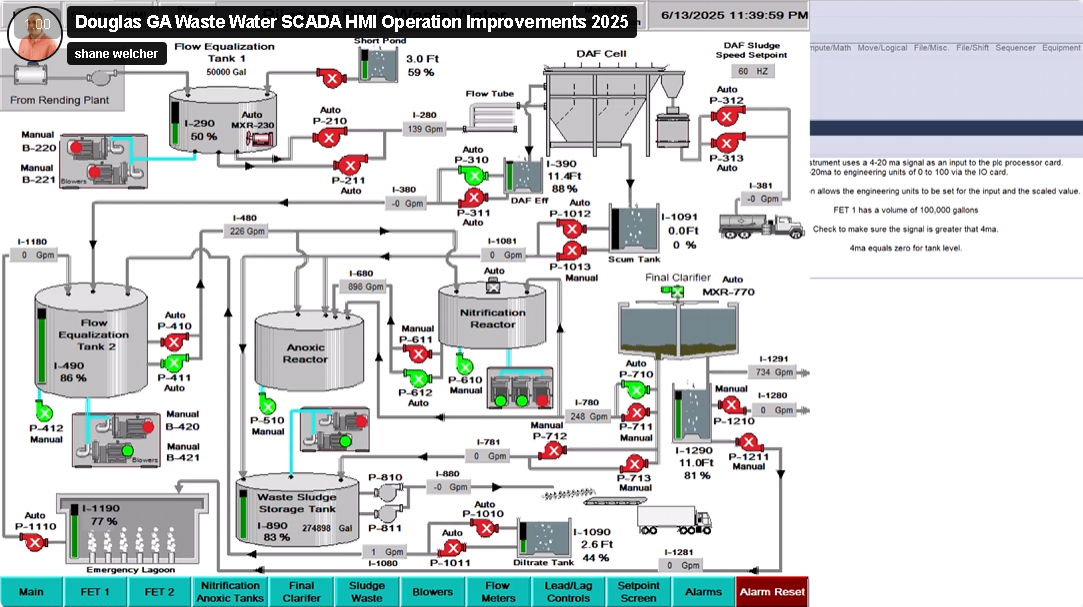

In this case study, this was a new system that was installed in 2022 by us. We first looked at all the design prints, which had the tanks, pumps, valves, and flow meters, then developed a scope of work, making the HMI system look as close to the designed prints as possible. All of the drives, flow meter, and devices were Ethernet through an IntelCenter. Our first task was to get all of the items commissioned and communicating. So we could build on a solid foundation from a controls perspective.

Simply put, we optimize our control automation of the wastewater plant to increase your productivity.

SERVICES

What We Do

Optimize Current Machines

We specialize in optimizing your current machines to increase their reliability through our years of experience.

Controls Integration

Our thoughts: You’ve already bought equipment, now it’s time to get things running to the best of their designed ability.

Our Standards

In this case study, when we identified any design issues that needed to be addressed, we ensured that they were brought to the plant’s attention so that the wastewater system could be made more user-friendly.

Full System Backups

We provided all updated files to the wastewater plant once the work was completed, plus we kept a copy in case you need anything. Standard operating procedures, Training, and controls program files.

Our Services

On this project, we specialized in Studio 5000 by upgrading the PLC master file to version 33. We also developed the FactoryTalk panelview to provide a user-friendly, reliable system.

Rockwell Automation Integrator

We developed the system and did electrical checkout, process checkout, and a Factory acceptance test during this project, so that the end of the curve could easily minimize time

Approach

Professional Automation Services & Technology Consulting

We are happy to say that the customer was more than pleased with the work that was done in such a short time. Installing a new DAF, all new tanks along with the pumps, flow meters, level sensors, and valves. Along with making their system more user-friendly.

We Create Fully Connected Systems So You Can Focus On Your Business

Let us help you achieve your goal, one opportunity at a time. Let our experience build you a better running machine.

PLC Controls Upgrades / Training

We provide cost-effective system upgrades along with a way to learn programmable control logic and human module interface for your machines so you have a support shaft with the best practices and easy tricks of the trade to make troubleshooting easy. The PLC programming training and standard operating procedures that we share with you are second to none leaving you with our company’s integrity of being an industry leader.

Putting Customers First

Our goal is to treat everyone of our customers with the honesty, respect, and opportunities that is deserved. No job is too small while no job is too big either. We achieve the challenges you face by doing what ever it takes to meet your controls needs.

Control Systems Optimization

Taking the machines you have right now and then analyzing them to see where system modifications can be performed to optimize what you already have. We have been able to do this by using industry best practices learned over the last 20 years in pulp and paper, bakeries, soda plants, and packing equipment to name a few. Building talent along the way so an easy transition can be done after we leave.

About Us

We originally started over 7 years ago as Online PLC Support which became a “GO-TO” place for people to learn PLC programming and to use it as a resource for industry standards. In our mission statement, we turn machine obstacles into improvement opportunities while increasing production..

We're Here To Help!

Office

Graniteville, SC 29829

Hours

M-F: 8 am – 10 pm

S-S: Closed -Unless Per Contract